Liquid Waste Management

Green Technologies Ltd. provides design, construction, and technical support services in Wastewater Treatment systems. The optimum choice is adopted, according to the type of waste (urban, industrial).

Construction of Wastewater Treatment Units

The Treatment units depending on the application, can be:

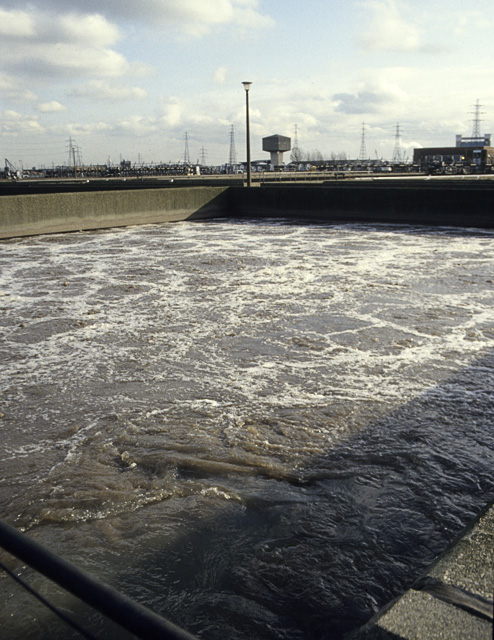

Conventional activated sludge-CAS systems

The activated sludge system is the most commonly used biological Wastewater Treatment system. The aim of these systems is the breakdown and removal of the organic load of the wastewater with biological oxidation. In such systems, a reduction of the total organic load of the waste is achieved with a simultaneous reduction of the lipids.

The most commonly applied process is the activated sludge method with prolonged aeration. This method is based on the faster and more complete degradation of the organic substances of the waste by the biosystems (microbial populations) that are developed in the bio flocs of the activated sludge, which are mainly consisted of bacteria and protozoa.

The advantages of this method are:

- ✓ Long aeration time resulting in a high degree of efficiency and a reduction to a minimum of excess mud.

- ✓ Small installation space, because it is not necessary to build a separate sludge treatment-disposal system (e.g. anaerobic sludge digester).

- ✓ Intensive aerobic conditions that protect the system from odors, the presence of insects, etc.

- ✓ Simple operation and maintenance that does not require skilled personnel.

Such biological wastewater treatment systems can be used in food industries achieving simultaneous removal of organics and nitrogen and are optimally selectable wastewater treatment technology (Best Available Technology – IPPC).

Membrane Bioreactor-MBR systems

The MBR system is consisting of a microfiltration or ultrafiltration membrane in a suspended growth bioreactor and is widely used in both municipal and industrial Wastewater Treatment Plants.

There are three membrane types:

- Hollow fibre (HF)

- Flat sheet (FS)

- Tubular or multi-tubular (ΜΤ)

The advantages of this method are:

- Low operating costs.

- Fast, easy and direct operation without odors.

- No need for monitoring and minimal maintenance requirement.

- Great flexibility in capacity increases.

- High reaction rate and efficiency that limits energy requirements.

- Exploitation of treated water for irrigation or fire fighting.

- Small space requirement (due to the large active surface of the filler material).

Moving Bed Bio Reactor-MBBR systems

MBBR treatment is combining the technology of activated sludge and biofilm-forming media, while eliminating or minimizing the shortcomings that tend to arise with conventional biological processes for wastewater treatment.

The advantages of this method are:

- Easy to use for inexperienced operators

- Requires little maintenance

- Resistant to shock loads

- Works efficiently with a low hydraulic retention time

Upflow anaerobic sludge blanket-UASB reactor

The UASB reactor through anaerobic wastewater treatment aims to remove organic pollution from wastewater, slurries and sludges. Anaerobic microorganisms convert organic pollutants into biogas, which contains methane and carbon dioxide.

The advantages of these reactor are:

- Utilization of residues and by-products with a negative ecological footprint for biogas production

- Reduction of gases, which burden the greenhouse effect

- Reduction of unpleasant odors

- Removal of high organic load

- Lower energy requirements

Compact Wastewater Treatment System for residences, industries and tourist accommodation

The proposed compact treatment system is SBR type (Sequencing Batch Reactor), where the biological treatment processes are carried out in the same space - tank.

By using the frequent alternation of aerobic and anoxic operating conditions, an effective bypass of the transitional stages of treatment is achieved with a reduction up to 40% of the organic matter requirements in the denitrification stage, 25% of the aeration requirements and 75% of the produced sewage sludge, while at the same time 63% increase in denitrification (nitrogen removal) rate is also achieved.

Biological wastewater treatment systems with simultaneous nitrogen removal (SBR type) are an optimally selectable wastewater treatment technology (Best Available Technology).

The advantages of these reactor are:

- Reduced fixed cost (smaller tank size) compared to conventional systems.

- Reduced operating costs (less requirements for chemicals, electricity for aeration and less amount of produced sewage sludge, the management of which is the major problem of existing conventional biological treatment plants).

- Very little space requirement because all processes take place in the same tank.

- Easy handling by the user, no need for specialized personnel.